November 18, 2024

By Sarah McQuate | UW News

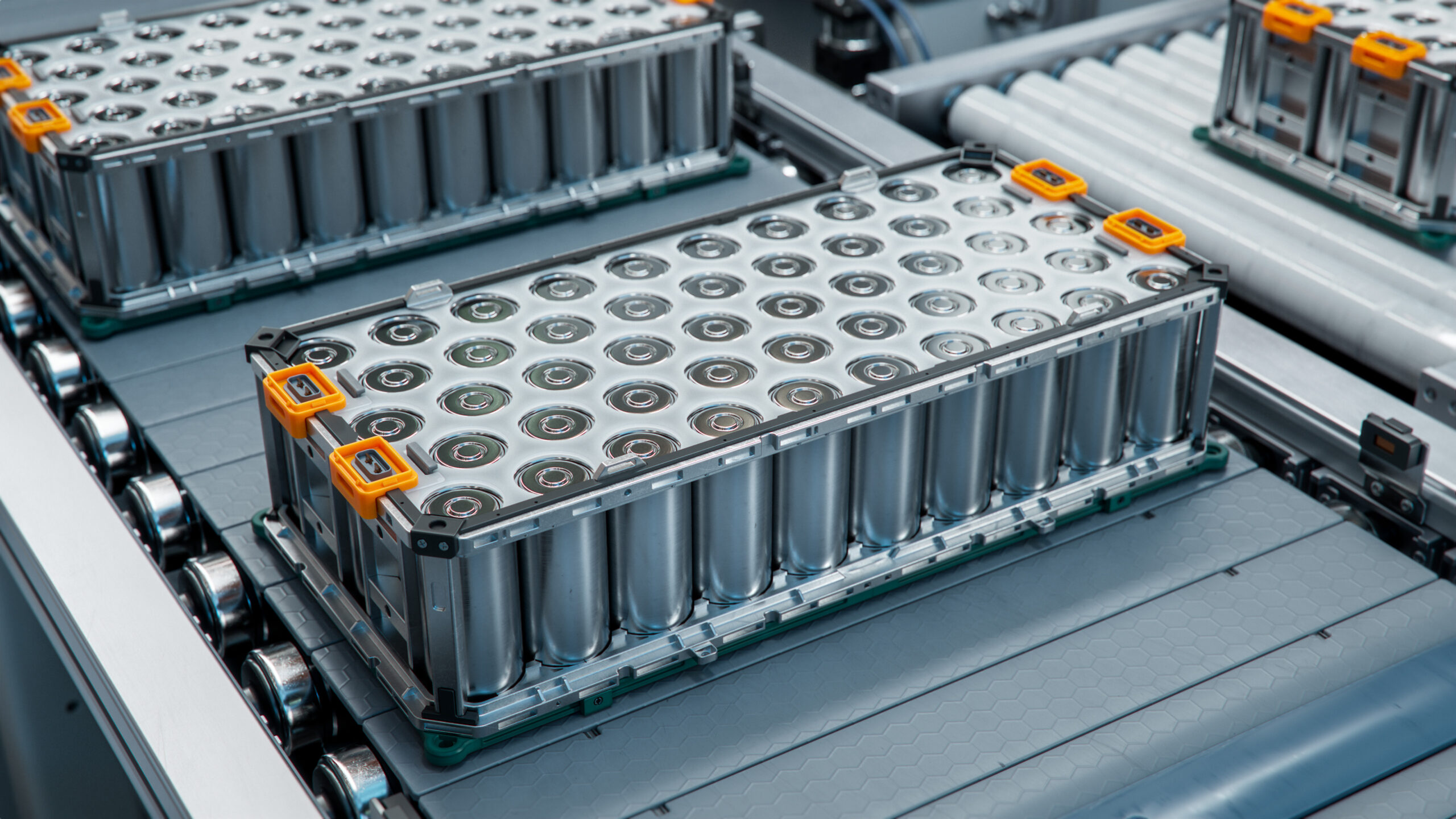

In September, the Biden-Harris Administration announced over $3 billion in funding to 25 projects focused on bringing battery manufacturing back to the U.S. as part of the administration’s “Investing in America” agenda. This new funding includes $200 million for a manufacturing and recycling project based in Moses Lake, Washington. While a new administration could bring changes, a focus on domestic manufacturing and growth in electric vehicles is likely to continue.

Jie Xiao, University of Washington professor of mechanical engineering, has worked on battery research for the past 20 years, including applications in electric vehicles, sensors and grid energy storage. UW News asked her about batteries and how academia can help support the growing domestic battery manufacturing industry.

You’ve compared a battery to a body. Can you elaborate on what you mean by that?

Jie Xiao: A battery is made up of many components including positive and negative electrodes, the electrolyte, current collectors and more. Similar to different body parts, each battery component has its own role and function. For example, the electrolyte is like the blood that every battery needs. If the electrolyte dries out, the battery dies. And usually the more electrolyte, the longer the lifespan of the battery. To make a battery work well and have a long life, all components need to work together.

Can you talk about how industry and academia can work together to advance battery technology?

JX: Through collaborations with industry over the years, I’ve seen that industry is facing many technical challenges that individual companies may not have the time or resources to understand and overcome. Here’s where academia could help. We researchers have many different scientific tools, facilities and smart students, but we need to know which problems to tackle first.

Being able to understand the true challenges industry is facing and being able to cross-validate potential innovative solutions at industry-relevant scales is the key to advancing battery technologies. If we can’t validate new materials or methods in practical batteries, our good ideas will remain on paper and never get implemented by industry.

Can you give an example of what this could look like?

JX: I’ve developed protocols for small battery testing vehicles called “coin cells” to bridge the knowledge gap between lab and industry. Almost all the battery research groups use coin cells to evaluate new materials or battery technologies in the lab.

The problem with coin cells is that the key parameters used to build and test those small cells are usually quite different from realistic full-sized batteries. For example, the amount of electrolyte in a coin cell could be 20 to 30 times more than in a practical battery. Therefore, if people observe a coin cell with a long lifecycle, it won’t necessarily translate into a long-lasting battery because the coin cell has an excessive amount of electrolyte — remember, that’s the battery’s “blood.”

I have published a few coin cell protocol papers to help our community standardize the testing conditions to ensure fast evaluation but still generate results that are relevant to industry.

What else are you working on to support battery manufacturing in the U.S.?

JX: One of my missions is to cultivate a more diversified workforce — from facilities operators to people with doctoral degrees — to support the battery manufacturing industry in the U.S.

I also plan to work with my colleagues at the UW to develop more industry-specific courses that include battery research projects. This will both accelerate the manufacturing process and help students understand how to use textbook knowledge to address real problems in battery manufacturing. These classes will also provide hands-on skills to the students so they will feel prepared to join the clean energy industry in the future.

Finally, I am also working with my colleagues at UW and the Pacific Northwest National Laboratory to organize a series of industry workshops in 2025 to help develop a roadmap for an upcoming testbed facility that has the aim of accelerating the technology translation from lab to market. This joint UW/PNNL project is supported by the Advanced Materials & Manufacturing Technologies Office of the Office of Energy Efficiency and Renewable Energy in the Department of Energy.

For more information, contact Xiao at jxiao4@uw.edu.