ME researchers are working to advance recyclable materials, renewable energy and more.

April 21, 2025 | By Lyra Fontaine

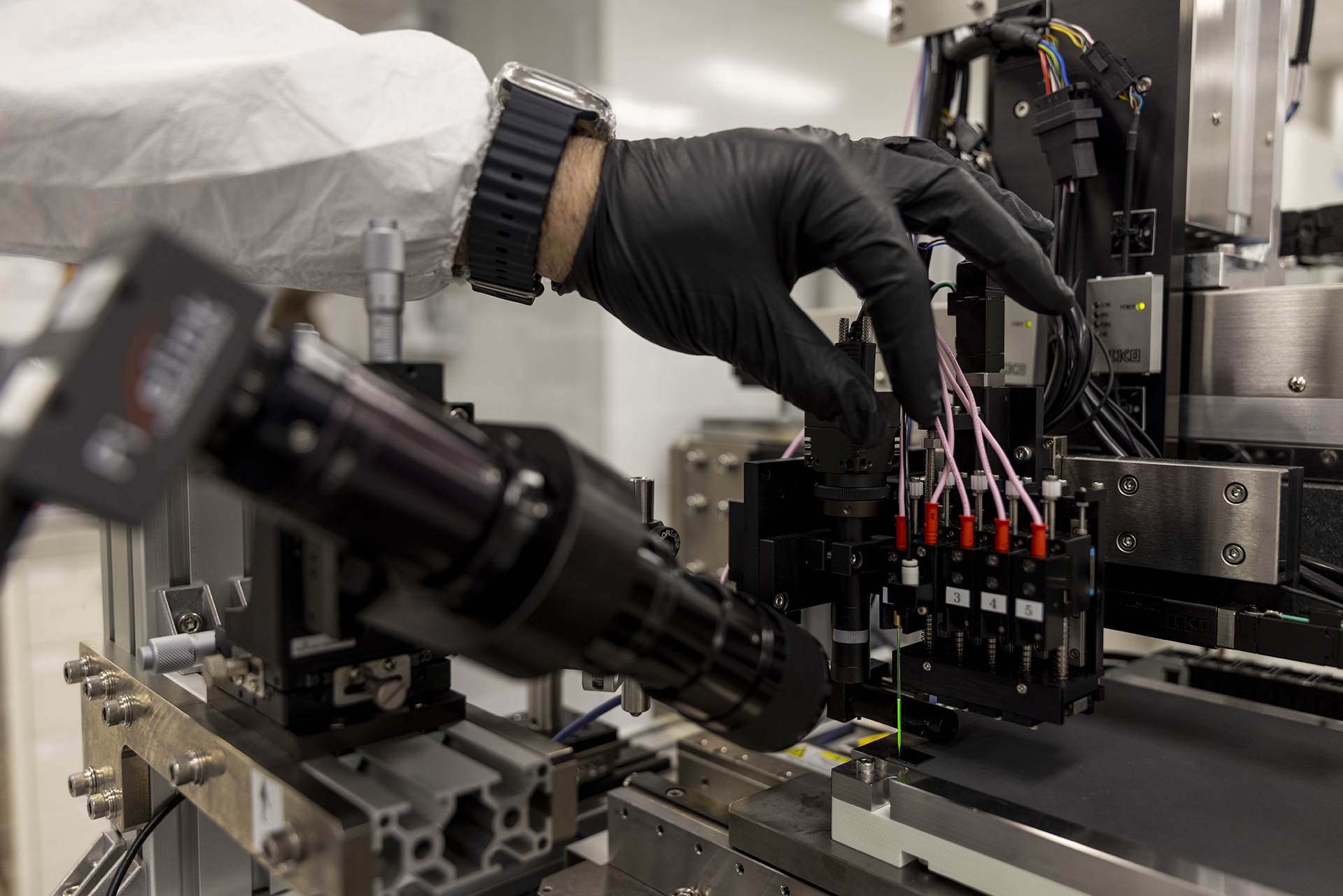

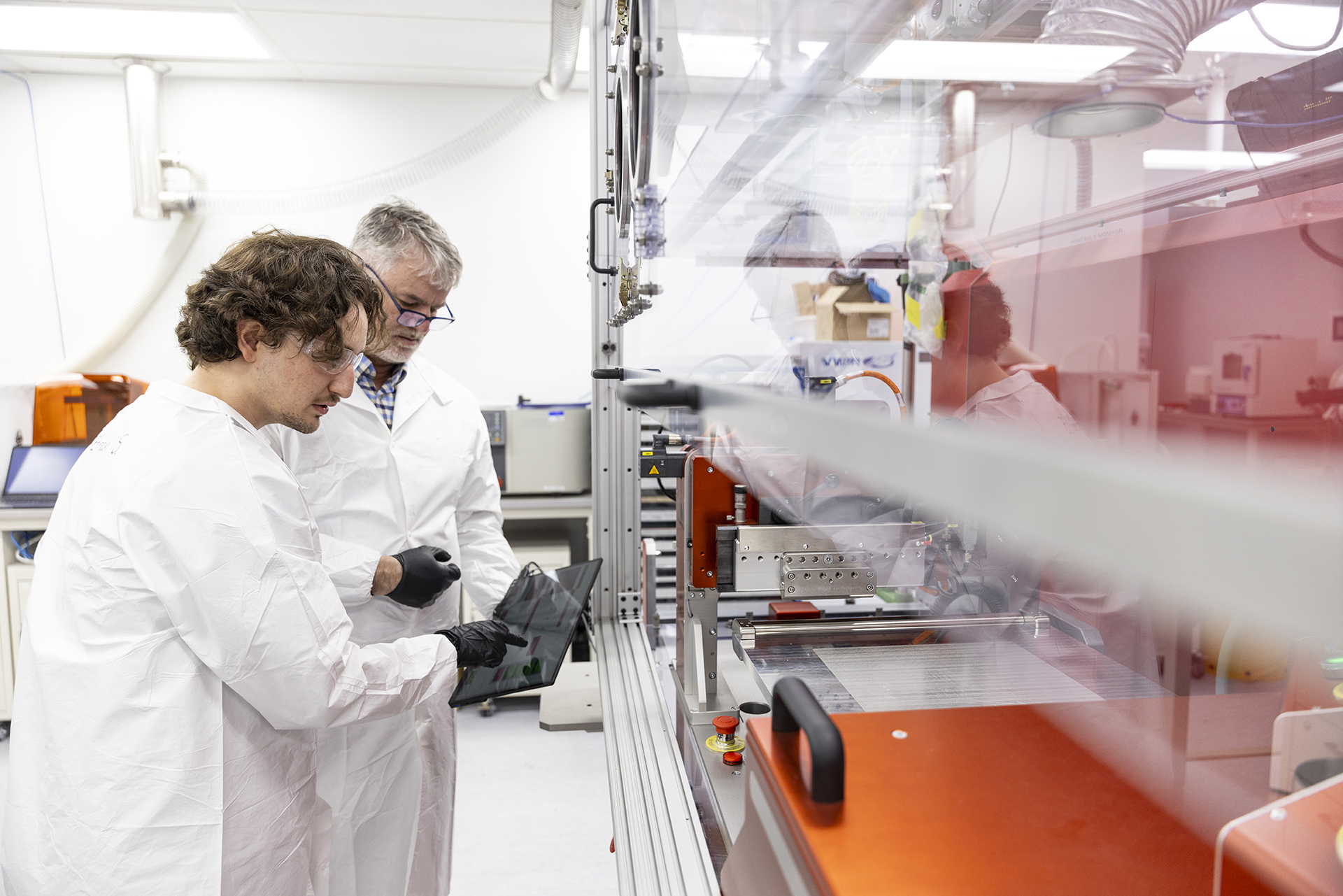

That’s why ME Ph.D. candidate Ethan Schwartz is working on increasing solar cell manufacturing in Associate Professor Devin MacKenzie’s lab. He works with perovskites, a semiconductor material with properties that can be tuned for high performance and easy-to-scale manufacturing.

``Producing more solar cells by reducing the capital cost of manufacturing would be a big step toward more widespread clean energy adoption.” — J. Devin MacKenzie

Silicon, which is conventionally used in solar cells, needs to be melted and processed at thousands of degrees Celsius. Perovskites are printable, starting as an ink and drying as a thin film with processing temperatures near 100°C, the temperature to boil water.

Schwartz identifies perovskite materials ingredients and process “recipes” to improve efficiency and prevent defects. Real-time sensors and a machine learning (ML) algorithm monitor and optimize the manufacturing process.

“The perovskite solar field evolves rapidly, with a new ‘recipe’ every few months,” MacKenzie says. “It’s important to adapt to new materials and methods that can be used to manufacture the large amount of solar panels required to meet our energy needs.”

ML and sensors help researchers refine solar cells by predicting performance, correcting flaws and reducing waste.

“An optimal solar cell could depend on various factors — chemical composition, deposition speed, temperature, humidity and more,” says Schwartz, a CEI Graduate Fellow. “We don’t have time to test each variable individually. ML accelerates discovery, helping us better predict a solar cell’s performance and lifespan.”

The researchers hope to improve solar panels’ efficiency — which is currently around 25 percent — at converting light into electrical power.

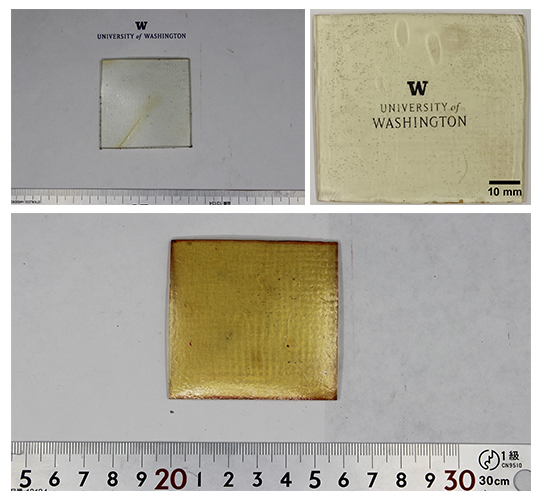

Beyond solar cells, researchers in MacKenzie’s lab are also 3D printing quantum dots. These tiny semiconductors are the foundation for photonic-based quantum devices, such as QLED displays and quantum computing.

ME Ph.D. candidate Greg Guymon, a CEI Graduate Fellow, uses a high-resolution electrohydrodynamic printer that applies electric fields to position and integrate these nanomaterials. Quantum dots are highly efficient at emitting light and can produce single photons, which are the basis of communicating between qubits in quantum computing with light.

This additive printing method also minimizes toxic heavy-metal and solvent use, Guymon says, and could make nanoscale manufacturing cheaper, more sustainable and more accessible than conventional subtractive processes like photolithography.

WCET researchers are creating quantum dots using a 3D printing method that could make nanoscale manufacturing cheaper and more sustainable than conventional processes. ME Ph.D. candidate Greg Guymon holds the photoactive materials before the printing process. (Photos by Dennis Wise/University of Washington)

Designing recyclable polymers with AI

Plastics, a type of polymer, are used in everything from cars and wind turbines to smartphones and medical devices — but they pose significant environmental challenges. Difficult to recycle and prone to degradation, plastics contribute to about 280 million tons of global waste produced each year, according to the United Nations.

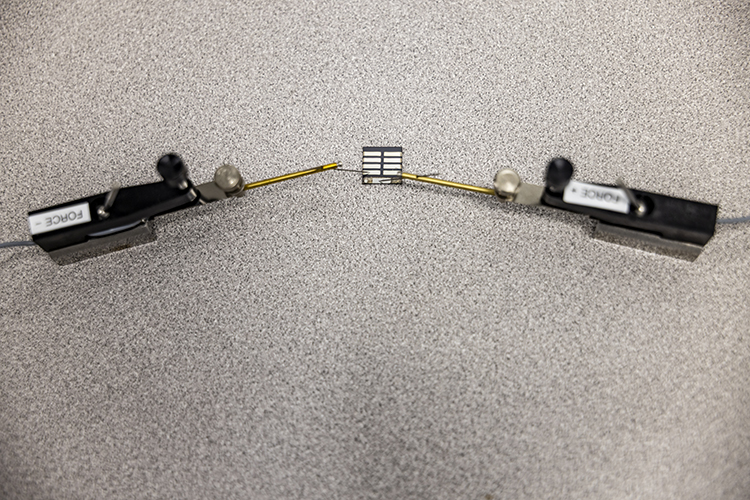

A new class of sustainable polymers called vitrimers could be a promising solution. Vitrimers can repair themselves without losing viscosity, thanks to chemical bonds that detach and reattach. But limited commercially available monomers or “building blocks” have slowed their development.

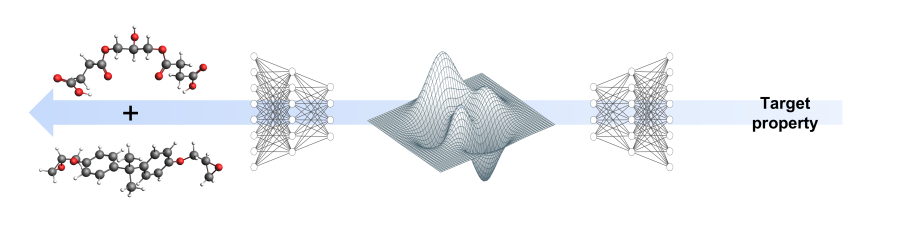

``A key innovation of ML in this work is that it can explore a wide chemical design space using a unique graph-based encoding method, efficiently predicting and optimizing polymer properties.`` — Yiwen Zheng

ME Assistant Professor Aniruddh Vashisth’s lab is working to speed up the discovery of new vitrimer compositions. In collaboration with Microsoft Research and Delft University of Technology, the researchers used artificial intelligence (AI) to design and synthesize recyclable polymers with targeted properties.

“Vitrimers are polymers that can be reused, recycled and reprocessed, and they could make a big difference,” says Vashisth, a CEI member faculty. “Our model can design recyclable polymers for any application, including electronics and aerospace composites.”

Instead of predicting a polymer’s properties based on its molecular building blocks — a typical approach — Vashisth’s team reversed the process. They virtually experimented on about 8,500 vitrimers with different molecular compositions to generate data for the ML model. The target property that the team focused on was glass transition temperature, the temperature when the material transitions from a solid to flexible state. Next, the researchers put the data into an ML model that learned the relationship between the molecular compositions and properties. They then asked the model to provide polymer structures with various glass transition temperatures.

“A key innovation of ML in this work is that it can explore a wide chemical design space using a unique graph-based encoding method, efficiently predicting and optimizing polymer properties,” says ME Ph.D. student Yiwen Zheng, a CEI Graduate Fellow who led the project. “This approach significantly accelerates the discovery of sustainable polymers by rapidly identifying novel materials with targeted characteristics beyond traditional experimental methods.”

After the user inputs the chosen temperature, the model creates molecular combinations of self-healing polymers. The ideal temperature depends on the application of the plastic–aircraft materials must withstand higher heat than water bottles or chairs.

Vashisth hopes that polymer chemists can use this tool to further design and create novel, sustainable polymers.

“We were able to embed part of the wisdom of a chemist in an ML model,” Vashisth says. “We asked the model to propose novel polymer chemistries for applications such as phone covers to aerospace composites. The model suggests synthesizable chemistries, but we still need a human’s chemical intuition for synthesis.”

ME postdoctoral researcher Agni Biswal synthesized the materials. Microsoft Research leads were Bichlien Nguyen and Jake Smith, and Delft University leads were Assistant Professor Siddhant Kumar and Prakash Thakolkaran.

Adapted from an article originally published by UW Mechanical Engineering.