Chemical engineers in the Pozzo Research Group are using open-source tools to build modular robots that can run multiple functions of complex experiments. This customizable framework helps alleviate the cost barrier of purchasing multiple, single-purpose commercial machines.

By Ro Stastny | UW Chemical Engineering

March 29, 2024

The Pozzo Research Group, led by chemical engineering (ChemE) professor Lilo Pozzo, is working to speed up the process of discovering and optimizing materials that have applications in clean energy, medicine, nanotechnology and more. To do this, researchers have used a series of commercially available equipment to conduct experiments through machine learning, high-throughput analysis, and advanced characterization through neutron and X-ray scattering.

In most cases of experimentation in polymer or colloidal materials, researchers can identify what the final material structure should be, but need to work backwards using solution-based processing. This is where multiple liquids are combined in varying proportions in order to work toward that desired outcome.

“Researchers can start by using prior knowledge and intuition to narrow down what chemicals or materials they need to mix, but to carry out each individual combination manually is thousands of hours of work,” says Dr. Kiran Vaddi, UW Data Science Postdoctoral Fellow in the Pozzo Research Group.

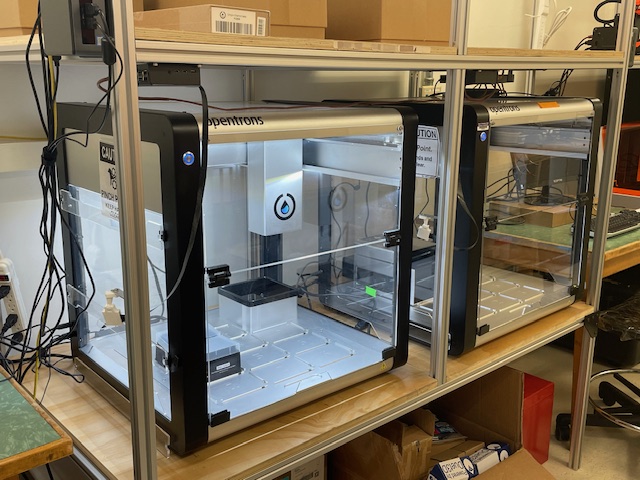

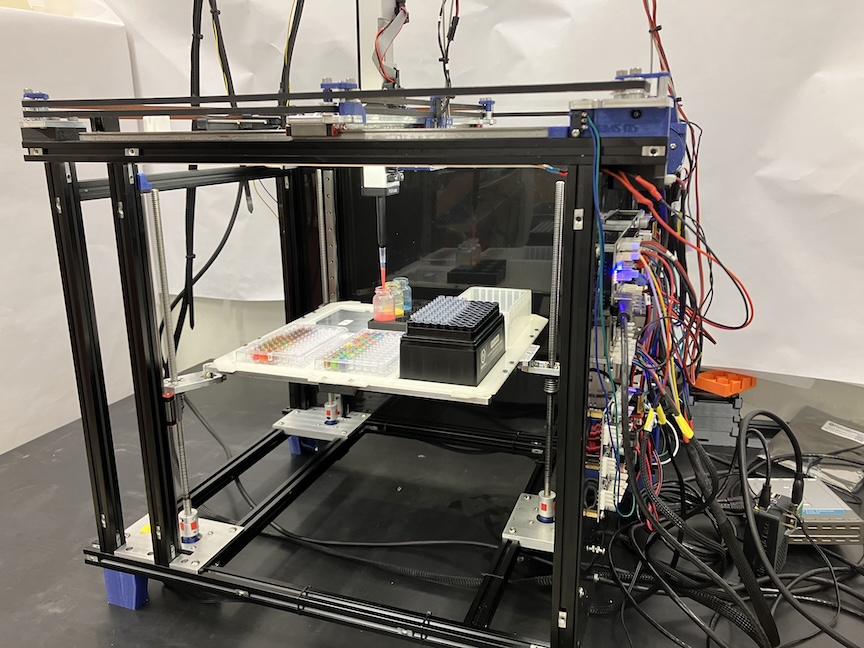

Commercially available robots are currently used in the Pozzo lab for high-throughput synthesis, and automate liquid material handling using a motorized pipette. With the push of a button, the machine can output dozens of liquid combinations in a precise volume in a matter of seconds.

Challenges of off-the-shelf tools

While the user-friendly nature of a commercial robot is helpful on some levels, it doesn’t come without issues. Typical machines are costly and run on closed-source software, which creates barriers and also dependencies. Even some of the more affordable commercial options, such as the Opentrons OT-2 currently priced at $13,000, are inaccessible for many smaller labs.

The OT-2 is also limited to liquid handling, and can only transfer materials that are compatible with a plastic pipette. If researchers want to add something solid or more volatile to the solution, this needs to be done separately, and could end up being more manual work now that the robot has made so many samples to work with. There also is no mechanism for introducing environmental factors like temperature changes to get more results.

“Adding more layers to the process generally means purchasing more costly equipment, and moves further away from the possibility of an automated process because now there are multiple separate machines to work with,” says Vaddi.

A solution in open-source hardware

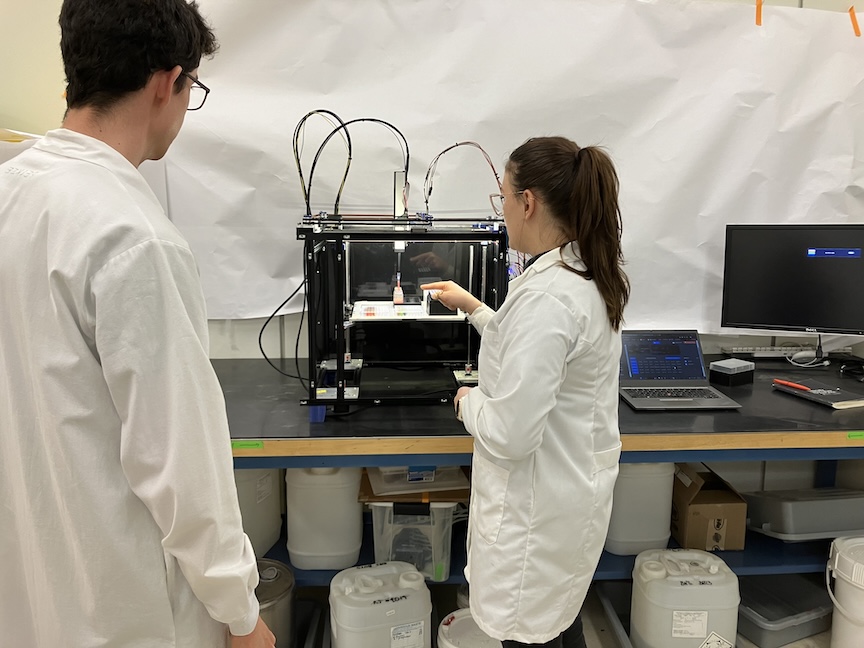

The Pozzo Research Group partnered with the Department of Human-Centered Design and Engineering (HCDE) to create a platform that would be completely customizable to their specific experimentation needs. With open-source hardware design provided by Machine Agency, the lab of HCDE professor Nadya Peek, ChemE researchers have built their own multi-functional robot with automated and autonomous experimentation for materials discovery in mind.

“Every lab needs different custom machines based on their niche, so the goal is to create hardware and software that allows domain experts to be able to build equipment that will serve their needs,” said Peek. “We design them so that all the pieces you need are available off-the-shelf, and can be assembled with basic tools or with anything you could easily access from a maker-space.”

This multi-process machine, called “Jubilee”, was built from open-hardware components, and is capable of the same liquid handling of the Opentrons OT-2 and more. With the open-hardware framework, Jubilee is designed to be a completely modular robot, with customizable functionality that brings capabilities of multiple lab machines into one. For example, the current Jubilee setup has an add-ons camera that can take photos to track visual changes in samples.

“It’s not an out-of-the-box option, since the entire thing needs to be built. But doing so helps us develop valuable skills in knowing and understanding how to fix the machine ourselves, without being dependent on outside customer support,” says Maria Politi, graduate student of chemical engineering and leader of the Jubilee project in the Pozzo lab.

The upfront time investment and steep learning curve pay off in the expanded functionality and possibilities of having a completely modular machine. And at roughly $2,000 for the starting hardware, it provides a much lower financial barrier than the commercial options.

“For now, even using Jubilee along with the OT-2 has dramatically accelerated the process,” said Politi.

With the open-source software powering Jubilee, any researcher can plug in their own laptop and use any python environment to work with the robot.

“Laboratory automation needs to work in tandem with autonomous experimentation to be efficient for real-world problems in materials discovery and design. The amount of data generated can easily overhaul what a human expert can comprehend, especially if it requires us to make decisions on the same time scale as the data generation of automated equipment,” Vaddi said. “By using these methods together, researchers can ultimately achieve a self-driving lab.”

Building a community

This project has brought other benefits to Pozzo lab researchers, aside from just being able to conduct closed-loop experiments faster.

“By developing a low-cost system that allows for closed-loop experimental procedures and making it all open-source and open-hardware, we can document and share everything with other labs. They can then use it and change it to suit their own needs,” said Politi.

Modular frameworks like Jubilee can be applied across all specialities, and provide an opportunity for interdisciplinary research groups and labs from all over the world to come together in a community of driven researchers and engineers, to share their challenges as well as their successes, collectively working toward more efficient methods for materials discovery and beyond.

“Working with the Pozzo group is so interesting because you won’t find more than a couple of people focused on the same research area. It’s great to see how everybody is integrating these new robotics tools in different ways,” says Politi.

Outreach and education

Pozzo lab members have traveled to conferences to present their robotics tools and have done a lot of outreach activities in educational settings.

Last summer, ChemE graduate student Brenden Pelkie brought Jubilee to Guadalajara, Mexico to teach a week-long course for Clubs de Ciencia MX, a non-profit organization offering STEM education programs to high school and early college students. Machine Agency and the Pozzo Research Group are also hosting a NSF-sponsored workshop at UW on April 25 for industry and academic researchers interested in lab automation. The workshop will bring together scientists from different labs and areas of expertise to talk about open-source tools and develop software to work with these customizable robots.

These educational and collaborative opportunities foster creativity and critical thinking, and encourage scientists and engineers to consider how open-source tools like Jubilee can bring unlimited possibilities to scientific research and experimentation.